No products

Categories

Manufacturers

Suppliers

- UAE Branch | TFICO

|

|

|

|

|

|

Customized Machine Design and Manufacturing

At TFI Co., we pride ourselves on our ability to design and manufacture machines that are tailored to meet the specific requirements of our customers. Whether you have a unique project in mind or need a machine customized to your factory's needs, our team is here to assist you. We understand the importance of starting from scratch and developing a design that aligns perfectly with your vision.

Durable Machines for the Middle East

Our machines are built to withstand the challenging climate conditions of the GCC states. With the extreme heat and humidity in the Middle East, we ensure that the components used in our machines, including hoses, valves, and hydraulic and electrical equipment, are highly resistant. This guarantees the longevity and reliability of our machines, enabling them to operate seamlessly in metalworking factories for a lifetime.

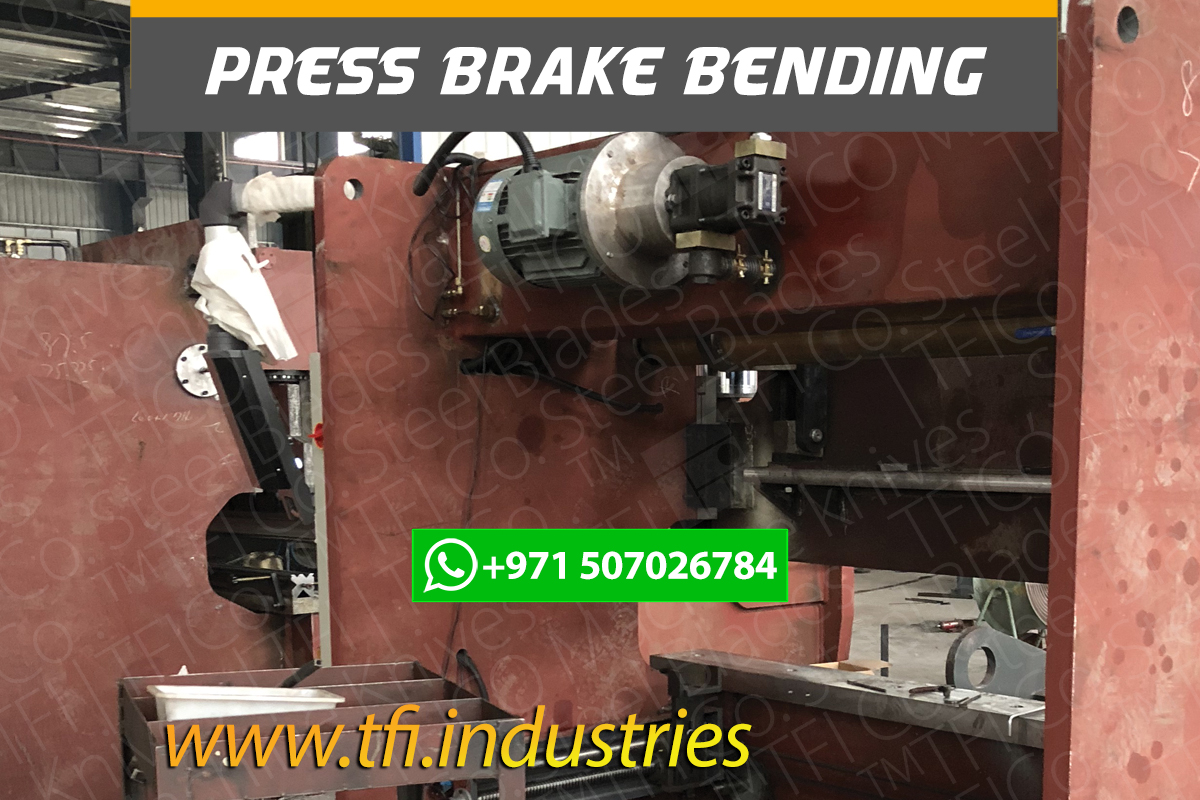

Tailored Solutions for Press Brake Machines

When it comes to press brake machines, we go beyond standard manufacturing. We modify our production line to cater to the specific applications of our customers. For example, we have the expertise to design and build a press brake machine with a length of 4000mm and a capacity of 200 tons. This machine is capable of handling heavy-duty bending tasks and provides the precision and performance required for your metalworking projects.

Designing Your Ideal Machine

Now, tell us about the machine you need. Let us know the maximum thickness you desire to bend, the desired length (such as 4000mm), and the required capacity (such as 200 tons). With this information, we will design the necessary tools and determine the ideal machine power to maximize efficiency and ensure the quality of your manufacturing processes.

Hydraulic Press Brake Machine 4000mm × 200 Tons

Professional Industrial Machine

State-of-the-art CNC hydraulic press brake designed for high-precision metal bending operations. With 4000mm working length and 200 tons bending force, this machine delivers exceptional performance for industrial sheet metal fabrication across UAE, Qatar, Oman, and Saudi Arabia.

Quick Specifications

- Bending Length: 4000mm (13.1 feet)

- Bending Force: 200 Tons

- Control System: CNC Computer Control

- Manufacturer: TFI Co. (Est. 1965)

- Target Market: GCC Countries

Complete Technical Specifications

Dimensions

Length: 4000mm

Opening Height: 420mm

Throat Depth: 320mm

Performance

Force: 200 Tons (2000 kN)

Speed: 8-10 mm/s

Accuracy: ±0.01mm

Power & Control

Motor: 22 kW

Voltage: 380V 3-Phase

CNC: 2-Axis Computer

Advanced Features & Capabilities

CNC Computer Control

2-axis CNC system with digital readout for precise angle and depth control. Program multiple bending sequences.

Hydraulic Crowning System

Automatic compensation system ensures uniform bending across the entire 4000mm length for consistent quality.

Safety Light Curtains

Advanced safety systems with light curtains and emergency stop buttons for operator protection during operation.

Back Gauge System

Motorized back gauge with CNC control for repeatable positioning. Memory storage for common bend setups.

Energy Efficient

Modern hydraulic system with variable frequency drive reduces energy consumption by up to 30% compared to older models.

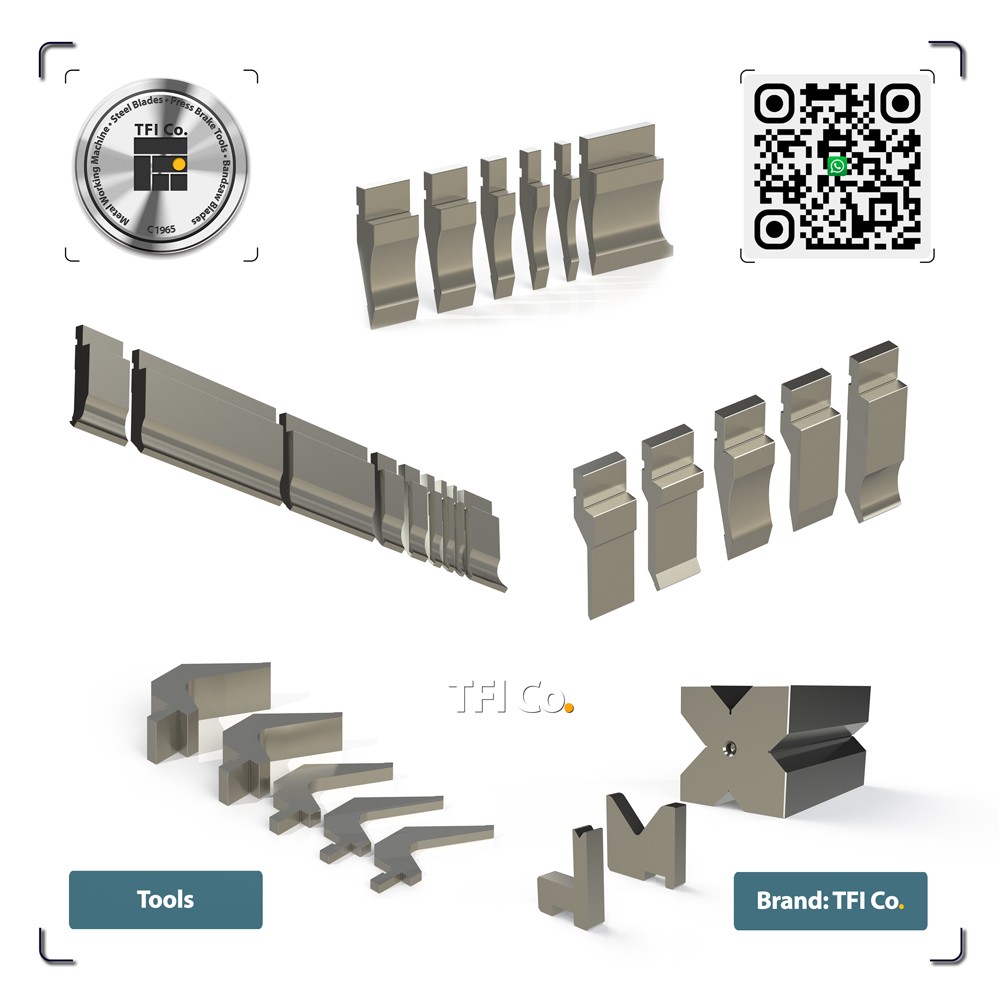

Tool Compatibility

Compatible with all standard press brake punches and dies. Quick-change tooling system for fast setup changes.

Industrial Applications

Perfect For These Industries:

This versatile machine handles a wide range of materials including mild steel, stainless steel, aluminum, and copper sheets up to 12mm thickness (depending on material). Ideal for producing brackets, frames, enclosures, panels, and complex bent parts with consistent quality.

GCC Regional Delivery & Support

UAE

Delivery: 45-60 days

Installation: Included

Training: 3 days

Qatar

Delivery: 50-65 days

Installation: Included

Training: 3 days

Oman

Delivery: 50-70 days

Installation: Included

Training: 3 days

Saudi Arabia

Delivery: 55-75 days

Installation: Included

Training: 3 days

Complete Turnkey Solution: All deliveries include professional installation, operator training, safety certification, and 1-year warranty with local technical support across GCC countries.

Customized Machine Design & Manufacturing

At TFI Co., we pride ourselves on our ability to design and manufacture machines that are tailored to meet the specific requirements of our customers. Whether you have a unique project in mind or need a machine customized to your factory's needs, our team is here to assist you. We understand the importance of starting from scratch and developing a design that aligns perfectly with your vision.

Durable Machines for the Middle East

Our machines are built to withstand the challenging climate conditions of the GCC states. With the extreme heat and humidity in the Middle East, we ensure that the components used in our machines, including hoses, valves, and hydraulic and electrical equipment, are highly resistant. This guarantees the longevity and reliability of our machines, enabling them to operate seamlessly in metalworking factories for a lifetime.

Tailored Solutions for Press Brake Machines

When it comes to press brake machines, we go beyond standard manufacturing. We modify our production line to cater to the specific applications of our customers. For example, we have the expertise to design and build a press brake machine with a length of 4000mm and a capacity of 200 tons. This machine is capable of handling heavy-duty bending tasks and provides the precision and performance required for your metalworking projects.

Designing Your Ideal Machine

Tell us about the machine you need. Let us know the maximum thickness you desire to bend, the desired length (such as 4000mm), and the required capacity (such as 200 tons). With this information, we will design the necessary tools and determine the ideal machine power to maximize efficiency and ensure the quality of your manufacturing processes.

Request Quote & Technical Consultation

Interested in This Machine? Get Expert Consultation

Our technical experts will help you with machine selection, customization options, financing, and installation planning.

Why Choose TFI Co. Machines?

60 Years Experience

Established in 1965, TFI Co. has been manufacturing precision industrial machinery for six decades.

Local Support

GCC-based technical support team available for installation, training, and maintenance services.

Quality Guarantee

All machines come with comprehensive warranty, spare parts availability, and quality certifications.