No products

Categories

Manufacturers

Suppliers

- UAE Branch | TFICO

About TFICo.

TFICo

TFI Co Started Manufacturing steel blades and machine knives from 1965

Over time the reputation of TFI has extended among customers, the quality of the blades and the durability of the cutters made clients confident about their Blade Supplier. TFI assured the market the promise of long term business relationship and close ties with the different departments of the companies.

We share the information of our 52 years experience with factories to increase their production efficiency. TFI Skilled Hands are trained to add value to alloy steel. We take advantage of modern technology combined with well educated human resources to prepare the finest steel blades and machine knives ever can be built. NOT everyone can Cook the Steel.

We know how to Mold Steel, What makes the Alloy Steel Different in their Characteristics and how to get what our customers production demands out of raw materials. The way the Brothers in TFI Differentiate the Alloy Steel Applications makes TFI to Exploit the the full hardness and great Strength of Steel Work for industries among the nations.

Leading Manufacturer Since 1965

Since 1965, TFI Co has been a leading manufacturer of steel blades and machine knives, catering to the diverse needs of industries worldwide. With a long-standing reputation for quality and durability, TFI has become the trusted supplier of choice for press brake tools and bending tools.

Exceptional Performance and Precision

Our press brake tools are meticulously crafted to deliver exceptional performance, precision, and longevity. Years of experience and expertise have allowed us to refine our manufacturing processes, ensuring that our tools meet the highest standards of quality and reliability.

Unleash Your Production Potential

When you choose TFI as your press brake tool supplier, you gain access to our extensive knowledge and experience. We understand the complexities of alloy steel and how to harness its unique characteristics to meet your specific production demands.

Experience Excellence

When it comes to press brake tools and bending tools, trust TFI Co to deliver excellence. Experience the difference our precision-crafted tools can make in your production processes. Contact us today and let us help you unlock the full potential of your press brake machine.

Our Production

We Never Stop Developing our tooling as solutions for customer projects, We Always find the new methods to have the most efficient production lines served with our engineered designs for press brake machines

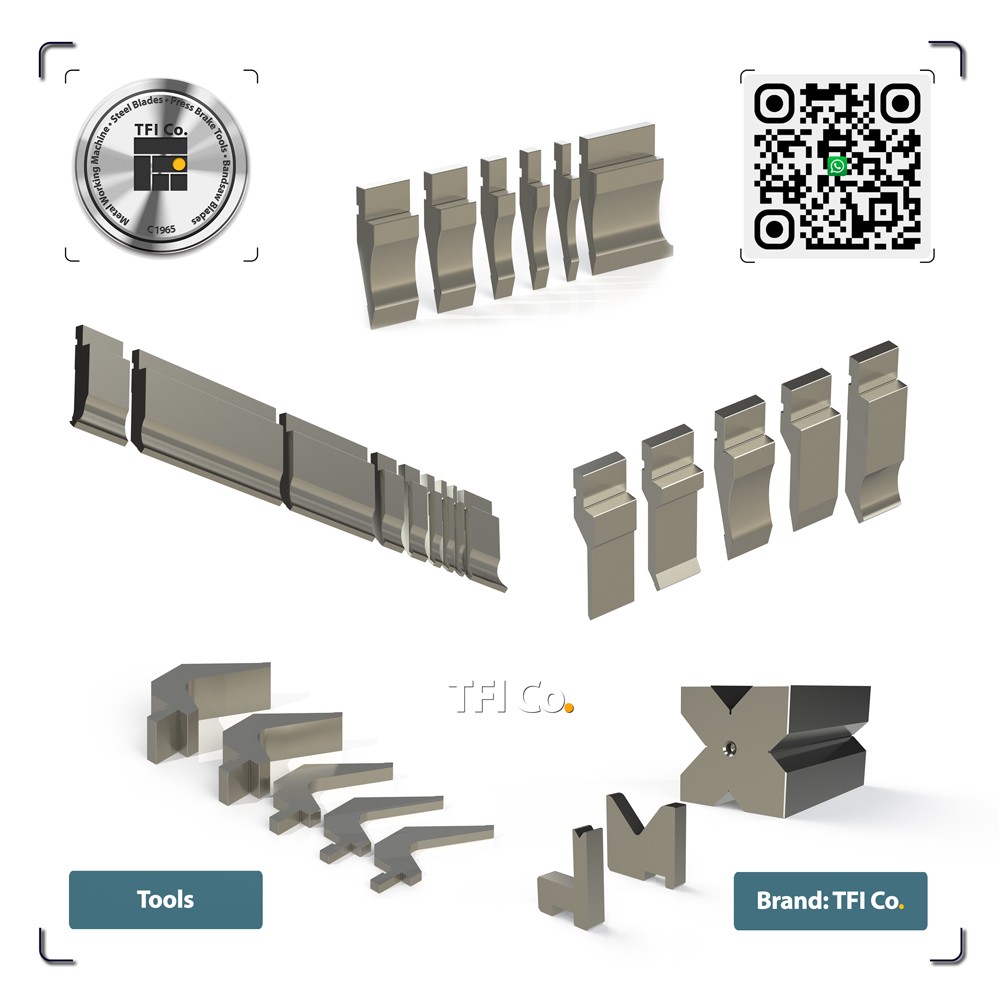

Precision-Crafted Press Brake Bending Tools

Our skilled hands are trained to add value to alloy steel, using a combination of modern technology and well-educated human resources. At TFI, we take pride in our ability to 'cook the steel' and create the finest press brake tools and machine knives in the industry.

Long-Term Partnerships in Middle east market

We believe in fostering long-term business relationships, and that's why we collaborate closely with our customers. By sharing our 52 years of experience, we help factories increase their production efficiency and achieve their goals.

Maximize Your Manufacturing Potential

TFI Co. stands apart from the competition through our deep understanding of alloy steel applications. We exploit the full hardness and strength of steel, allowing industries across nations to maximize their manufacturing potential.

TFI Co. - 60 Years of Manufacturing Excellence

Founded in 1965

TFI Co. was established in 1965 by visionary founder M.D. Dasturi, beginning a legacy of precision engineering in metalworking tools. For six decades, we have been the trusted name in press brake tools manufacturing, serving industries across the Middle East with uncompromising quality and innovation.

From our humble beginnings manufacturing steel blades and machine knives, we have grown into a comprehensive supplier of bending punches, bending matrix, V blocks, gooseneck punches, and complete press brake machines - all engineered to meet the demanding requirements of modern metal fabrication.

Quick Facts

- Founded: 1965

- Founder: M.D. Dasturi

- Specialty: Press Brake Tools

- Markets: UAE, Qatar, Oman, Saudi Arabia

Manufacturing Excellence & Expertise

Precision Engineering

Advanced metallurgy expertise in alloy steel processing with tolerances to 0.01mm for perfect bending results.

Quality Assurance

Every tool undergoes rigorous testing and inspection to ensure durability and performance in demanding applications.

Continuous Innovation

We never stop developing new tooling solutions and efficient production methods for evolving customer needs.

"Not Everyone Can Cook the Steel"

This is our motto - a testament to our deep understanding of alloy steel characteristics. We know how to mold steel, how to exploit the full hardness and strength of different alloy compositions, and how to transform raw materials into precision tools that meet your exact production demands. Our skilled craftsmen combine 60 years of metallurgical knowledge with modern technology to create the finest press brake tools in the industry.

Serving the GCC Market with Pride

TFI Co. is your trusted partner across the Gulf Cooperation Council - delivering precision-engineered press brake tools and machines designed specifically for the demanding Middle East climate and industrial applications.

United Arab Emirates

Main Office: Dubai

Service: Same-day quote

Delivery: 7-14 days

Qatar

Service Center: Doha

Service: Technical support

Delivery: 10-14 days

Oman

Service Center: Muscat

Service: Local support

Delivery: 10-14 days

Saudi Arabia

Service Center: Riyadh

Service: Regional support

Delivery: 14-21 days

Middle East Climate Durability Guaranteed

Our press brake tools are specifically engineered to withstand the extreme heat and humidity of the GCC climate. We use heat-resistant hydraulic components, corrosion-proof coatings, and climate-tested materials that ensure reliable performance for decades in demanding Middle East metalworking environments - from 45°C summer heat to dusty industrial conditions.

Complete Press Brake Tools Range

Bending Matrix & V Blocks

Lower dies in various V-openings (4V to 16V) for different material thicknesses. Hardened to 58-62 HRC for extended tool life.

Gooseneck Bending Punches

Specialized upper tools with offset design for deep box bending and complex geometries. Available in multiple angles and radii.

Straight Bending Punches

Standard upper punches for general air bending and bottom bending operations. Precision ground to tight tolerances.

Detachable Radius Punches

Modular system with interchangeable radius tips (R0.5 to R10) for versatile forming operations and quick tool changes.

Hemming Tools

Specialized tooling for creating folded edges and hemmed flanges in sheet metal panels for automotive and construction applications.

Press Brake Machines

Complete CNC hydraulic press brakes from 40 to 300 tons, 1000mm to 4000mm working length. Custom configurations available.

Quality Standards & Certifications

ISO Quality Systems

Certified manufacturing processes ensuring consistent quality across all products and batches.

Material Certification

All alloy steels tested and certified with material traceability documentation provided.

Performance Testing

Rigorous hardness testing (HRC), dimensional inspection, and load testing before shipment.

Our Quality Promise

- Hardness Guarantee: All tools hardened to 58-62 HRC with uniform heat treatment

- Dimensional Accuracy: Precision ground to ±0.01mm tolerance specifications

- Material Traceability: Full documentation of steel composition and heat treatment

- Extended Warranty: 12-month warranty on all press brake tools and machines

- Lifetime Support: Technical consultation and spare parts availability for the life of your equipment

Contact TFI Co.

Call Us

+971 800 0120096

Sun-Thu: 8AM-5PM

Sat: 8AM-1PM

Email Us

Contact via Website

Quick response

within 24 hours

Visit Us

Dubai, UAE

Serving GCC

since 1965

Ready to Experience TFI Co. Quality?

Contact our technical team today for expert consultation, product recommendations, and custom tooling solutions for your press brake operations.

60 Years of Excellence | Trusted by 1000+ Factories Across GCC | Same-Day Technical Support

Why Leading Manufacturers Choose TFI Co.

60 Years Heritage

Since 1965, six decades of continuous innovation and refinement in press brake tool manufacturing.

GCC Local Support

Service centers across UAE, Qatar, Oman, and Saudi Arabia with same-day technical assistance.

Custom Solutions

Tailored press brake tools and machines designed to your exact specifications and requirements.

Climate Tested

Tools engineered for extreme GCC heat and humidity - proven durability in 45°C+ environments.

Quality Certified

ISO-certified manufacturing with full material traceability and comprehensive testing protocols.

Lifetime Support

Ongoing technical consultation, spare parts availability, and training for the life of your equipment.